Izinto eziphathekayo

| Umzimba | Intsimbi |

| Gqiba | Zinc iPlated |

| Mandrel | Intsimbi |

| Gqiba | Zinc iPlated |

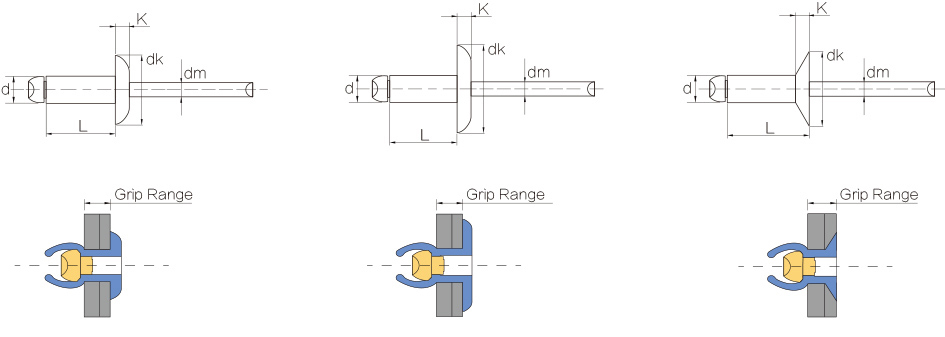

| Uhlobo lweNtloko | IDome, iCSK, iFlange enkulu |

Inkcazo

| D1 NOM. | I-DRILL NO. &UBUKHULU bengqula | ART.CODE | ULUHLU LOKUBAMBA | L(MAX) | D NOM. | K MAX. | P MIN. | CHEBA LBS | I-TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0.876-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 1000 4450N | 1240 5520N |

| I-SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| I-SS812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| I-SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| I-SS816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| I-SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Isicelo

Intsimbi evulekileyo yee-rivets ezingaboniyo ayipheleli nje ngokulula ukuyisebenzisa, ukusebenza kakuhle okuphezulu, ingxolo ephantsi, inokunciphisa ukuqina kwabasebenzi kunye nezinye iimpawu, kodwa kunye nokuqina konxibelelwano.Iirivethi zentsimbi zinokwahlulwa zibe yi-dome head rivet, ii-countersunk rivets kunye ne-rivet enkulu ye-flange head.Amandla okuqina kunye nokucheba kweerivethi zentsimbi ezingaboniyo ziphezulu kakhulu kunerivets eziqhelekileyo zealuminiyam.Isetyenziswa ngokubanzi kwimizi-mveliso, inokuhlangabezana neemfuno zesicelo samandla aphezulu.

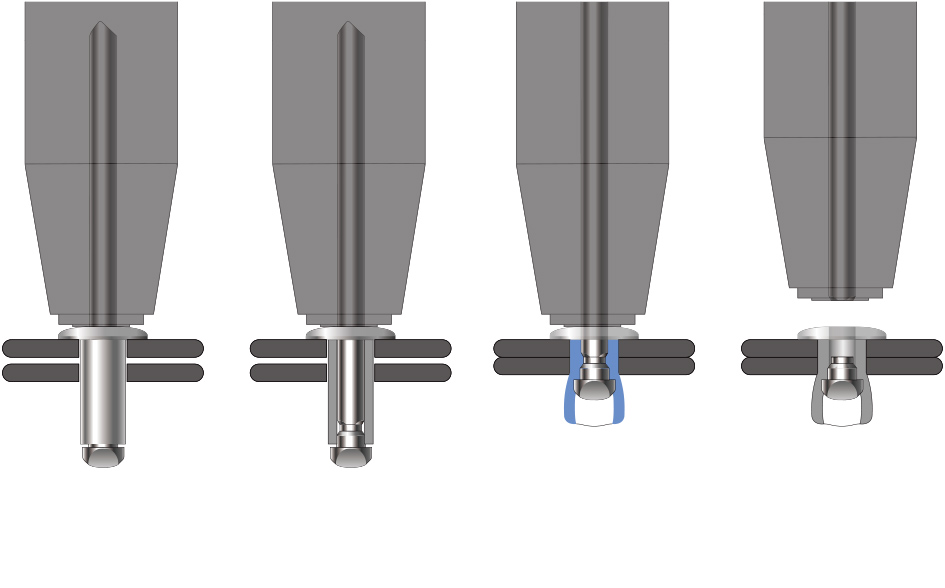

Iingxaki kunye nezizathu xa usebenzisa i-rivet pop:

4.I-pop rivet iyatsalwa: I-rivet mandrel itsalwe ngokupheleleyo kwi-rivet, kwaye i-mandrel yaphukile.Emva kwe-riveting, shiya imingxuma engenanto kwi-rivet.

Izizathu zokutsalwa zezi: rivet kakhulu mandrel tension;ububanzi obuncinci be-mandrel caps;izinto zokuthambisa ezithambileyo;umphezulu womngxuma ongaphakathi uthanjiswe kakhulu.

I-5.Intloko ye-Jump okanye i-drum ayinelanga: Xa udonsa i-rivets, i-rivet core iphuma ngokupheleleyo, okanye i-rivet ayifuni.

Izizathu zalo mcimbi zezi: ulawulo lwe-tensile luphantsi kakhulu xa i-nail core yenziwe;umzimba we-riveting uphezulu (i-annealing engalingani);

6. Relax emva kwe-riveting: Emva kwe-riveting, umzimba we-riveting ukhululekile kumngxuma wokusebenza.