Izinto eziphathekayo

| Umzimba | IAluminiyam(5050 5052 5056) | Intsimbi | Isinyithi esingenasici ● | ||||

| Gqiba | Ikhazimlisiwe, Ipeyintiwe | Zinc iPlated | Ilungisiwe | ||||

| Mandrel | Aluminiyam | Intsimbi | Yenziwe ngentsimbi eshayinayo | Intsimbi | Aluminiyam | Intsimbi | Isinyithi esingenasici ● |

| Gqiba | Ilungisiwe | Zinc iPlated | Ilungisiwe | Zinc iPlated | Ilungisiwe | Zinc iPlated | Ilungisiwe |

| Uhlobo lweNtloko | IDome, iCSK, iFlange enkulu | ||||||

Inkcazo

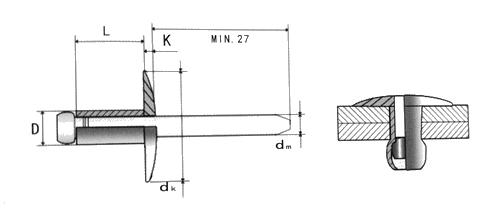

| D NOM. | I-DRILL NO.&UBUKHULU bengqula | ULUHLU LOKUBAMBA | L (MAX) | dk NOM. | K MAX | P MIN. | ||

| INCH | MM | INCH | MM | |||||

| 1/8" 3.2mm | #30 3.3-3.4 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | 0.375" 9.5 | 0.065" 1.65 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||

| 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||

| 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||

| 0.176-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||

| 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||

| 5/32" 4.0mm | #20 4.1-4.2 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.468" 12.0 | 0.075" 1.90 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||

| 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||

| 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||

| 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||

| 3/16" 4.8mm | #11 4.9-5.0 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.625" 16.0 | 0.092" 2.33 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||

| 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||

| 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||

| 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||

| 0.626-0.750 | 15.9-19.1 | 0.950 | 24.1 | |||||

| 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||

| 0.876-1.000 | 22.5-25.4 | 1.200 | 30.5 | |||||

| 1.001-1.125 | 25.4-28.6 | |||||||

Isicelo

Iirivethi ezinkulu zeflange ezingaboniyo, ububanzi bale ntloko ye-rivet bonyuke kakhulu xa kuthelekiswa neerivethi ezingaboniyo eziqhelekileyo.Xa i-riveting kunye nezixhumi, i-rivet inendawo enkulu yoqhagamshelwano, indawo yokuxhasa eyomeleleyo, kwaye inokunyusa amandla e-torque.I-rivet enkulu ye-flange entloko inokumelana noxinzelelo lwe-radial ephezulu.

Iirivethi zetsimbi yentsimbi engenastainless ikakhulu zisebenzisa ucingo lwentsimbi okanye ipleyiti njengemathiriyeli ekrwada, elandelwa sisihloko esibandayo okanye isitampu kunye nothotho lweenkqubo.Kudume kakhulu ukusebenzisa insimbi engenasici ukwenza iirivets zepop, kodwa iirivets zentsimbi ezingenasici, zineempawu ezine:

1. Ukumelana nokushisa okuphezulu kwee-rivets zensimbi ezingenasici ezingaboniyo.Njengoko ukuqina kwensimbi engenasici kunamandla, iirivets emva kokuveliswa zinokumelana ne-oxidation eqinile, kwaye zinokusebenza ngokuqhelekileyo phantsi kwamaqondo okushisa aphezulu ngaphandle kokuphazamiseka okukhulu kwiqondo lokushisa eliphezulu.I-rivets ye-stainless pop rivets idluliswa emva kokuveliswa, ekwazi ukumelana nokushisa okuphezulu.

2. Iimpawu ezibonakalayo ze-stainless steel pop rivets zinezinga eliphezulu elibi.Xa kuthelekiswa ne-carbon steel wire rod, sinokubona ukuba izinga elibi le-rivets ye-stainless steel blind rivets liphindwe kahlanu kune-carbon steel.Kukho i-coefficient yokwandisa kwiindawo eziqhelekileyo.Ngovavanyo, siyazi ukuba ukuba iqondo lobushushu liphezulu, i-coefficient yokwandiswa kwee-rivets zensimbi engenasici iya kuphuculwa ukuya kuthi ga kwinqanaba elithile.

3. Umthamo wokuthwala umthwalo we-stainless steel pop rivets unamandla ngakumbi kwi-stainless steel pop rivets.Nangona zingenakuthelekiswa neebholiti eziphezulu, zikwahlangabezana neemfuno zabantu abaqhelekileyo.

4. Iimpawu zoomatshini zentsimbi ye-pop rivets.Kwiipropati zomatshini, sinokwazi ukuba ezininzi zazo zihlobene ngokusondeleyo neengcingo zensimbi ezingenasici.I-Handan Wodecy Co., Ltd iirivethi ezingaboniyo zensimbi ezingenasici zenziwa ikakhulu nge-304 okanye i-316 yocingo okanye ipleyiti, kwaye aziyi kugqwala, zinokumelana ne-corrosion ephezulu kunye nokumelana nokucheba okuphezulu.Ezi zihambelana ngokusondeleyo kwiipropati zensimbi engenasici.Ngophuhliso oluqhubekayo lwe-pop rivets, ezi zixhobo zomatshini ziba namandla kwaye zomelele.