Izinto eziphathekayo

| Umzimba | IAluminiyam ( 5052) | Intsimbi | Isinyithi esingenasici ● | |

| Gqiba | Ilungisiwe | Zinc iPlated | Ilungisiwe | |

| Mandrel | Intsimbi | Yenziwe ngentsimbi eshayinayo | Intsimbi | Isinyithi esingenasici ● |

| Gqiba | Zinc iPlated | Ilungisiwe | Zinc iPlated | Ilungisiwe |

| Uhlobo lweNtloko | IDome, iCSK, iFlange enkulu | |||

Inkcazo

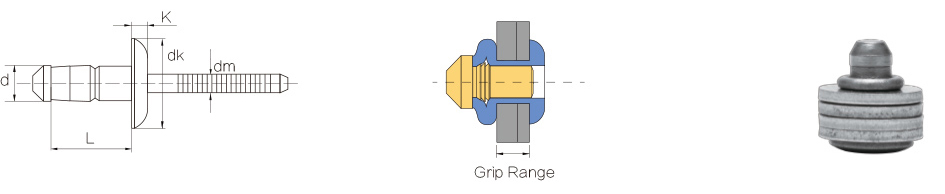

| Ubungakanani | Drill | Icandelo elinguNomb. | M | Uluhlu lokubamba | B | K | E | Cheba | Ukuqina |

| max | max | max | max | KN | KN | ||||

| 3.2 (1/8") |  | BBP61-0408 | 8.9 | 1.0-3.0 | 6.6 | 1.1 | 2.1 | 1.6 | 2.0 |

| BBP61-0411 | 11.4 | 3.0-5.0 | 6.6 | 1.1 | 2.1 | 1.7 | 2.0 | ||

| BBP61-0414 | 13.6 | 5.0-7.0 | 6.6 | 1.1 | 2.1 | 3.2 | 2.0 | ||

| 4.0 (5/32") |  | BBP61-0509 | 10.1 | 1.0-3.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 |

| SSP01-0512 | 12.5 | 3.0-5.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 | ||

| BBP61-0516 | 15.1 | 5.0-7.0 | 8.0 | 1.5 | 2.6 | 5.2 | |||

| 4.8 (3/16") |  | BBP61-0611 | 12.9 | 1.5-3.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

| BBP61-0614 | 15.5 | 3.5-6.0 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 | ||

| BBP61-0618 | 18.5 | 6.0-8.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

Isicelo

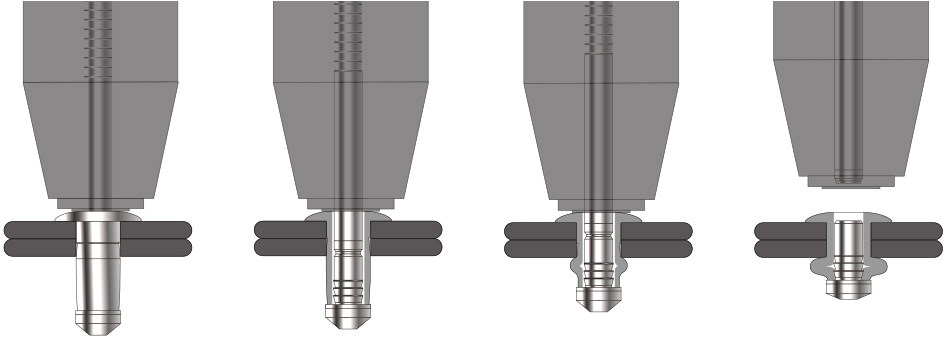

Iirivethi ezingaboniyo ze-Uni-Grip luhlobo lwezakhiwo ezingaboniyo.Iirivethi ezingaboniyo zohlobo lwe-Uni grip zitsala imipu ye-rivet kwiintlobo ze-rivethi enye xa i-riveting rivets, ibambe iindawo ezibini zesakhiwo ukuba zikhutshwe, kwaye zinciphise uxinzelelo kumphezulu wecandelo lolwakhiwo.Ifanelekile kwi-riveting ephezulu.Iindawo ezibhityileyo ezakhiweyo.Unempembelelo ethile yokukhusela kwiindawo ezijikelezayo ukuze ugweme i-deformation ye-riveting holes kunye nokutshabalalisa iindawo ezijikelezayo.

Eyona njongo iphambili ye-Uni grip type blind rivets zizithuthi, iinqanawa, izakhiwo, oomatshini, umbane, iinqwelomoya, izitya, izinyusi kunye namanye amashishini.

Zeziphi iindlela zokuthintela umhlwa kwiiBlind Rivets

1. Ukucwenga

Ukufakela i-rivet eyimfama, le ndlela kukubeka i-rivet kwisisombululo setsimbi, kwaye emva koko usebenzise i-current ukusebenzisa i-layer yensimbi ebusweni, enemiphumo emininzi kulo mgca wesinyithi.

2. Ukugquma oomatshini

I-mechanical plating ye-rivet eyimfama kukuvumela ukuba iincinci zetsimbi zibanda zifakwe kwii-rivets ezingaboniyo ukuqinisekisa ukuba umphezulu we-rivet oyimfama unemiphumo ethile.I-coating yomatshini kunye ne-electroplating iyafana, kodwa iindlela zahlukile.Iziphumo kunokuthiwa ziyafana.

3. Unyango olushushu

Kunyango olushushu lweendawo ezingaboniyo ze-rivet, ezinye iindawo ze-rivet ze-pop zinzima, ngoko ke unokufudumeza ii-rivets ze-pop ukuze uqinisekise ukuba i-rivet ye-pop inobunzima obaneleyo.Yingakho unyango lobushushu lwenziwa.

4. Intshukumo yomphezulu

Ukudlula i-rivet surface eyimfama kunemisebenzi emibini ephambili.Enye kukuphucula ubulukhuni bee-rivets, kwaye enye kukunciphisa kakhulu inqanaba le-oxidation yee-rivets ezingaboniyo.

-

IAluminiyam eneAluminiyam iMandrel Tri-Fold Blind R...

-

IPneumatic Blind Rivet Gun

-

Intsimbi eNcinci ngeStainless Stainless Open Type ...

-

I-Steel Uni Grip Rivet yoLwakhiwo oluPhezulu lwaMandla...

-

I-Aluminiyam ene-Steel Mandrel Uhlobo olukhulu lweFlange B...

-

Intsimbi engatyiwa ngentsimbi yeMandrel La...